Protoboard Gauge Wire . Ready to buy some solid hookup wire. awg22 or awg24 generally work well. they have a little advantage: Let’s take a closer look at the types of breadboard wires you can use. Thin wire can be difficult to strip and brittle. You spend zero time on measuring how long wire you need, and you spend zero time on wire striping. stick to solid core wire with a gauge of around 22awg for best results. The ideal thickness for a breadboard wire is awg22 (0.64mm). Anything bigger than awg22 can mangle the breadboard connector (i've had to. these wires are essential for connecting components on the breadboard and can make a big difference in the functionality, presentation, and complexity of the wiring of a project. a convenient way to assemble an electronic circuit, without having to solder components, is to use a prototyping solderless.

from tresdprinttech.com

these wires are essential for connecting components on the breadboard and can make a big difference in the functionality, presentation, and complexity of the wiring of a project. awg22 or awg24 generally work well. stick to solid core wire with a gauge of around 22awg for best results. Anything bigger than awg22 can mangle the breadboard connector (i've had to. Thin wire can be difficult to strip and brittle. The ideal thickness for a breadboard wire is awg22 (0.64mm). Let’s take a closer look at the types of breadboard wires you can use. Ready to buy some solid hookup wire. You spend zero time on measuring how long wire you need, and you spend zero time on wire striping. they have a little advantage:

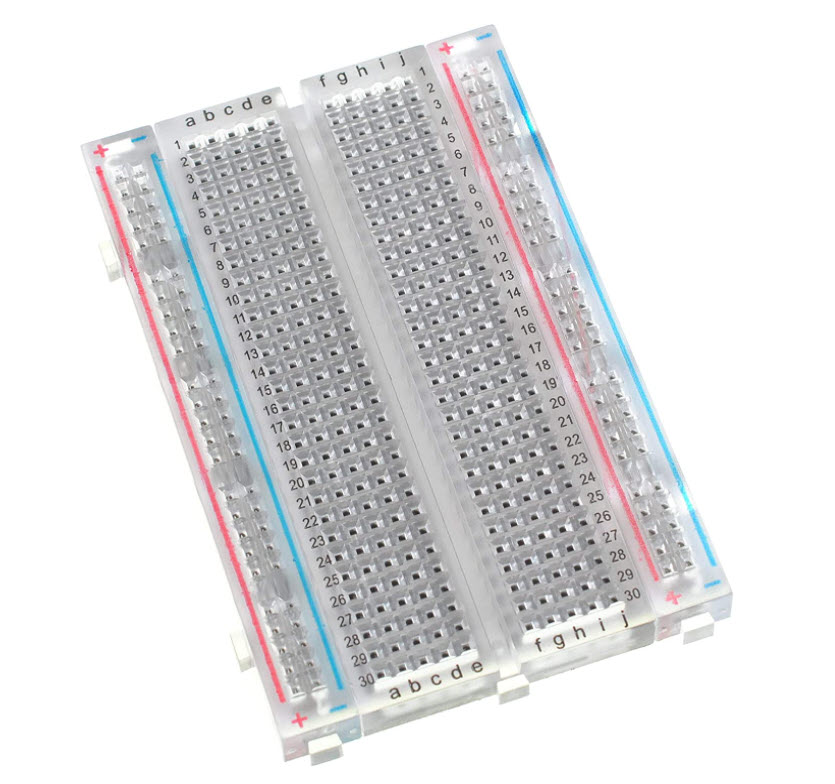

Protoboard 400 puntos Transparente TresD Print Tech

Protoboard Gauge Wire The ideal thickness for a breadboard wire is awg22 (0.64mm). Ready to buy some solid hookup wire. Thin wire can be difficult to strip and brittle. Let’s take a closer look at the types of breadboard wires you can use. Anything bigger than awg22 can mangle the breadboard connector (i've had to. stick to solid core wire with a gauge of around 22awg for best results. The ideal thickness for a breadboard wire is awg22 (0.64mm). a convenient way to assemble an electronic circuit, without having to solder components, is to use a prototyping solderless. awg22 or awg24 generally work well. these wires are essential for connecting components on the breadboard and can make a big difference in the functionality, presentation, and complexity of the wiring of a project. You spend zero time on measuring how long wire you need, and you spend zero time on wire striping. they have a little advantage:

From labdefisica2014.blogspot.com

Uso del Protoboard Preparaduría de Laboratorio de Física Protoboard Gauge Wire Anything bigger than awg22 can mangle the breadboard connector (i've had to. awg22 or awg24 generally work well. Let’s take a closer look at the types of breadboard wires you can use. Ready to buy some solid hookup wire. Thin wire can be difficult to strip and brittle. these wires are essential for connecting components on the breadboard. Protoboard Gauge Wire.

From electronics.stackexchange.com

breadboard Soldering 12 gauge wire to protoboard Electrical Engineering Stack Exchange Protoboard Gauge Wire You spend zero time on measuring how long wire you need, and you spend zero time on wire striping. The ideal thickness for a breadboard wire is awg22 (0.64mm). stick to solid core wire with a gauge of around 22awg for best results. Let’s take a closer look at the types of breadboard wires you can use. they. Protoboard Gauge Wire.

From www.330ohms.com

Protoboard Grande 800 puntos 330ohms Protoboard Gauge Wire awg22 or awg24 generally work well. The ideal thickness for a breadboard wire is awg22 (0.64mm). stick to solid core wire with a gauge of around 22awg for best results. they have a little advantage: a convenient way to assemble an electronic circuit, without having to solder components, is to use a prototyping solderless. Ready to. Protoboard Gauge Wire.

From www.amazon.es

HUAREW Protoboard Dupont wire Cables incluye placa de pruebas de 830 puntos de pruebas de 400 Protoboard Gauge Wire Ready to buy some solid hookup wire. a convenient way to assemble an electronic circuit, without having to solder components, is to use a prototyping solderless. Thin wire can be difficult to strip and brittle. they have a little advantage: The ideal thickness for a breadboard wire is awg22 (0.64mm). You spend zero time on measuring how long. Protoboard Gauge Wire.

From makerspaces.northeastern.edu

Soldering Basics DIY Training Northeastern Makerspaces Protoboard Gauge Wire Thin wire can be difficult to strip and brittle. they have a little advantage: these wires are essential for connecting components on the breadboard and can make a big difference in the functionality, presentation, and complexity of the wiring of a project. Let’s take a closer look at the types of breadboard wires you can use. awg22. Protoboard Gauge Wire.

From www3.gobiernodecanarias.org

Protoboard 2 pruebas para examen Blog de Aula de Pantaleón Hernández Rodríguez Protoboard Gauge Wire Let’s take a closer look at the types of breadboard wires you can use. stick to solid core wire with a gauge of around 22awg for best results. The ideal thickness for a breadboard wire is awg22 (0.64mm). awg22 or awg24 generally work well. a convenient way to assemble an electronic circuit, without having to solder components,. Protoboard Gauge Wire.

From www.gsnetwork.com

Breadboard Components Tools + Power Supply Protoboard Gauge Wire You spend zero time on measuring how long wire you need, and you spend zero time on wire striping. Anything bigger than awg22 can mangle the breadboard connector (i've had to. Thin wire can be difficult to strip and brittle. Ready to buy some solid hookup wire. stick to solid core wire with a gauge of around 22awg for. Protoboard Gauge Wire.

From www.alibaba.com

830 Points Test Breadboard Protoboard Wire Power Module Buy Power Moudle,Breadboard,Wire Protoboard Gauge Wire You spend zero time on measuring how long wire you need, and you spend zero time on wire striping. these wires are essential for connecting components on the breadboard and can make a big difference in the functionality, presentation, and complexity of the wiring of a project. awg22 or awg24 generally work well. Anything bigger than awg22 can. Protoboard Gauge Wire.

From studylib.net

Protoboard and Wiring Details Protoboard Gauge Wire a convenient way to assemble an electronic circuit, without having to solder components, is to use a prototyping solderless. The ideal thickness for a breadboard wire is awg22 (0.64mm). Ready to buy some solid hookup wire. stick to solid core wire with a gauge of around 22awg for best results. Let’s take a closer look at the types. Protoboard Gauge Wire.

From www.e-ika.com

Cables dupont para protoboard de 20cm, 120uds Protoboard Gauge Wire Let’s take a closer look at the types of breadboard wires you can use. Anything bigger than awg22 can mangle the breadboard connector (i've had to. Ready to buy some solid hookup wire. these wires are essential for connecting components on the breadboard and can make a big difference in the functionality, presentation, and complexity of the wiring of. Protoboard Gauge Wire.

From www.reddit.com

3D protoboard wiring... r/diyelectronics Protoboard Gauge Wire Anything bigger than awg22 can mangle the breadboard connector (i've had to. a convenient way to assemble an electronic circuit, without having to solder components, is to use a prototyping solderless. The ideal thickness for a breadboard wire is awg22 (0.64mm). Let’s take a closer look at the types of breadboard wires you can use. awg22 or awg24. Protoboard Gauge Wire.

From uae.microless.com

Platinum Breadboard P/N B301000 30AWG Tin Plated Copper WireWrapping Wire Gauge Solid Core Protoboard Gauge Wire Let’s take a closer look at the types of breadboard wires you can use. Ready to buy some solid hookup wire. The ideal thickness for a breadboard wire is awg22 (0.64mm). they have a little advantage: You spend zero time on measuring how long wire you need, and you spend zero time on wire striping. these wires are. Protoboard Gauge Wire.

From www.allaboutcircuits.com

The Best Wire for Breadboarding News Protoboard Gauge Wire a convenient way to assemble an electronic circuit, without having to solder components, is to use a prototyping solderless. Anything bigger than awg22 can mangle the breadboard connector (i've had to. awg22 or awg24 generally work well. You spend zero time on measuring how long wire you need, and you spend zero time on wire striping. stick. Protoboard Gauge Wire.

From www.alibaba.com

830 Points Test Breadboard Protoboard Wire Power Module Buy Power Moudle,Breadboard,Wire Protoboard Gauge Wire Ready to buy some solid hookup wire. You spend zero time on measuring how long wire you need, and you spend zero time on wire striping. these wires are essential for connecting components on the breadboard and can make a big difference in the functionality, presentation, and complexity of the wiring of a project. Thin wire can be difficult. Protoboard Gauge Wire.

From www.nepal.ubuy.com

Buy FIRMERST PCB Breadboard Hook Up Wire Kit 22 Gauge Solid Tinned Copper 28 Feet8.5M Each Spool Protoboard Gauge Wire Anything bigger than awg22 can mangle the breadboard connector (i've had to. these wires are essential for connecting components on the breadboard and can make a big difference in the functionality, presentation, and complexity of the wiring of a project. Thin wire can be difficult to strip and brittle. You spend zero time on measuring how long wire you. Protoboard Gauge Wire.

From www.pcboard.ca

60 Piece Deluxe Breadboard Jumper Wires Canada Protoboard Gauge Wire Let’s take a closer look at the types of breadboard wires you can use. a convenient way to assemble an electronic circuit, without having to solder components, is to use a prototyping solderless. they have a little advantage: Anything bigger than awg22 can mangle the breadboard connector (i've had to. these wires are essential for connecting components. Protoboard Gauge Wire.

From jessicayin.com

DIY Protoboard Shields and Wire Management for Prototyping — Jessica Yin Protoboard Gauge Wire Let’s take a closer look at the types of breadboard wires you can use. Anything bigger than awg22 can mangle the breadboard connector (i've had to. Ready to buy some solid hookup wire. a convenient way to assemble an electronic circuit, without having to solder components, is to use a prototyping solderless. these wires are essential for connecting. Protoboard Gauge Wire.

From www.allaboutcircuits.com

The Best Wire for Breadboarding News Protoboard Gauge Wire Thin wire can be difficult to strip and brittle. stick to solid core wire with a gauge of around 22awg for best results. Let’s take a closer look at the types of breadboard wires you can use. these wires are essential for connecting components on the breadboard and can make a big difference in the functionality, presentation, and. Protoboard Gauge Wire.